Contact Us

Contact Us

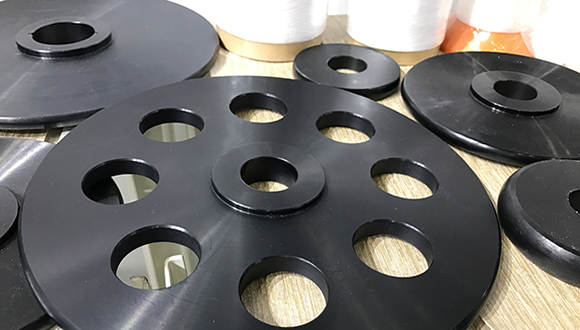

Adhaness® Advanced Composites can be used at the temperature from 150℃ to 380℃ for a long term. These materials offer excellent sliding friction and chemical resistance at high temperatures for long. Other inherent properties of Adhaness® Advanced Composites also include fatigue resistance, low specific gravity, super strength, flame retardancy, toughness and creep resistance.

By scientifically adding some substances like carbon fiber, glass fiber, glass bead, aramid fiber, PTFE, minerals, graphite, metal powder, molybdenum disulfide, stainless steel fiber, carbon nanotubes, addictives into the resin material and perfectly combine them together, our technical experts gained a series of modified Adhaness® Advanced Composites which can easily substitute the function of some kinds of metals such as copper, iron, aluminum alloy, stainless steel, and titanium alloy and etc.

In addition,FUGEO can provide customized services to meet our customers’ differentiated demands by modifying these materials’ properties. The custom-tailored properties cover structural enhancement, electric conduction and electronic screening, flame retardancy, self-lubrication and wear resistance, long (short) carbon fiber reinforcement, long (short) glass fiber reinforcement(LFT), high specific gravity, low specific gravity, medical level quality, heat resistance, toughness, thermal conduction and electric insulation, electric and thermal conduction, laser marking, and magnetic detection. We can also provide nano-plastics, spraying-free plastics and special coloring services. And FUGEO will continue to honor our words by creating values for our customers with unique products and services.

Highlights:

1. Excellent mechanical strength and good toughness

2. Excellent heat resistance and low specific gravity

3. Excellent chemical resistance and radiation resistance

4. Excellent flame retardancy

5. Excellent creep resistance and fatigue resistance

6. Excellent self-lubrication and wear resistance

Limitations:

1. Relatively small output

2. Relatively higher Cost

Adhaness® PBI, one of the best thermoplastic engineering plastics, can be used at high temperature up to 310℃ for a long time. The modified Adhaness® PBI can resist a temperature as high as 380℃, and its instant heat tolerance point can reach 760℃.Adhaness® PBI can remain stable in acidic or alkaline environment. What’s worth mentioning is that this plastic material has a towfold increase in strength compared with Vespel plastics, and has half the hardness of glass at the same time. Because of its excellent comprehensive properties unmatched by other plastics,Adhaness® PBI is surely the best choice for our customers despite the cost. It enables our customers to find the most powerful solution.

By scientifically adding some substances like carbon fiber, glass fiber, glass bead, aramid fiber, PTFE, minerals, graphite, metal powder, molybdenum disulfide, stainless steel fiber, carbon nanotubes, addictives into the resin material and perfectly combine them together, our technical experts gained a series of modified Adhaness® PBI which can easily substitute the function of some kinds of metals such as copper, iron, aluminum alloy, stainless steel, and titanium alloy and etc.

What’s more, we also provide customized services to meet our customers’ varied needs. And FUGEO will continue to honor our words by creating values for our customers with unique products and services.

Adhaness® TPI features high strength and rigidity, excellent creep resistance, and chemical resistance. It can be used for a long time at elevated temperatures. Even under high pressure and at fast speed,Adhaness® TPI can still maintain valuable properties of wear resistance, electrical insulation, flame retardancy, high purity and airtightness (in vacuum environment), low temperature resistance. Either as a structural material or as a functional one,Adhaness® TPI has been fully recognized as the material with great application prospects. Because of its prominent characteristics and synthesis effects, it is now known as "protion solver".

By scientifically adding some substances like carbon fiber, glass fiber, glass bead, aramid fiber, PTFE, minerals, graphite, metal powder, molybdenum disulfide, stainless steel fiber, carbon nanotubes, addictives into the resin material and perfectly combine them together, our technical experts gained a series of modified Adhaness® TBI which can easily substitute the function of some kinds of metals such as copper, iron, aluminum alloy, stainless steel, and titanium alloy and etc.

What’s more, we also provide customized services to meet our customers’ varied needs. And FUGEO will continue to honor our words by creating values for our customers with unique products and services.

Adhaness® PAI offers better flowability and solves the processing difficulty when compared with TPI. It can be shaped into all kinds of sophisticated products with injection molding technology, and thus, the production efficiency will be greatly improved.Adhaness® PAI has better heat resistance, molding strength, dimensional stability and wear resistance than those of other engineering plastics. We can effectively modify and improve the properties of Adhaness® PAI, such as by adding a special lubricant to improve its wear resistance and by adding glass fiber and carbon fiber so that its heat resistance and mechanical strength can be improved. Through these ways, we can offer various choices for our customers.

By scientifically adding some substances like carbon fiber, glass fiber, glass bead, aramid fiber, PTFE, minerals, graphite, metal powder, molybdenum disulfide, stainless steel fiber, carbon nanotubes, addictives into the resin material and perfectly combine them together, our technical experts gained a series of modified Adhaness® PAI which can easily substitute the function of some kinds of metals such as copper, iron, aluminum alloy, stainless steel, and titanium alloy and etc.

What’s more, we also provide customized services to meet our customers’ varied needs. And FUGEO will continue to honor our words by creating values for our customers with unique products and services.

Adhaness® PEEK, with outstanding properties, is a kind of special engineering plastics that can be used at high temperatures. Compared with other special engineering plastics,Adhaness® PEEK is resistant to a high temperature up to 260℃, and its characteristics include self-lubrication, chemical corrosion resistance, flame retardancy, exfoliation resistance, wear resistance, anti-radiation, and super good mechanical function and so on.

By scientifically adding some substances like carbon fiber, glass fiber, glass bead, aramid fiber, PTFE, minerals, graphite, metal powder, molybdenum disulfide, stainless steel fiber, carbon nanotubes, addictives into the resin material and perfectly combine them together, our technical experts gained a series of modified Adhaness® PEEK which can easily substitute the function of some kinds of metals such as copper, iron, aluminum alloy, stainless steel, and titanium alloy and etc.

In addition, FUGEO can provide customized services to meet our customers’ differentiated demands by modifying these materials' properties. The custom-tailored properties cover structural enhancement, electric conduction and electronic screening, flame retardancy, self-lubrication and wear resistance, long (short) carbon fiber reinforcement, long (short) glass fiber reinforcement(LFT), high specific gravity, low specific gravity, medical level quality, heat resistance, toughness, thermal conduction and electric insulation, electric and thermal conduction, laser marking, and magnetic detection. We can also provide nano-plastics, spraying-free plastics and special coloring services. And FUGEO will continue to honor our words by creating values for our customers with unique products and services.

Adhaness® PEI is a high performance engineering thermoplastic that can be used at a high temperature up to 170℃. Compared with other special engineering plastics,Adhaness® PEI has such excellent characteristics as heat resistance, fatigue resistance, creep resistance, self-lubrication, wear resistance, chemical corrosion resistance, flame retardancy, anti-radiation and low temperature resistance, together with excellent mechanical and electrical properties.

By scientifically adding some substances like carbon fiber, glass fiber, glass bead, aramid fiber, PTFE, minerals, graphite, metal powder, molybdenum disulfide, stainless steel fiber, carbon nanotubes, addictives into the resin material and perfectly combine them together, our technical experts gained a series of modified Adhaness® PEI which can easily substitute the function of some kinds of metals such as copper, iron, aluminum alloy, stainless steel, and titanium alloy and etc.

In addition, FUGEO can provide customized services to meet our customers’ differentiated demands by modifying these materials’ properties. The custom-tailored properties cover structural enhancement, electric conduction and electronic screening, flame retardancy, self-lubrication and wear resistance, long (short) carbon fiber reinforcement, long (short) glass fiber reinforcement(LFT), high specific gravity, low specific gravity, medical level quality, heat resistance, toughness, thermal conduction and electric insulation, electric and thermal conduction, laser marking, and magnetic detection. We can also provide nano-plastics, spraying-free plastics and special coloring services. And FUGEO will continue to honor our words by creating values for our customers with unique products and services.

TECHNICAL DATA SHEETS

Further understanding of the product data

TECHNICAL DATA SHEETS

Further understanding of the product data

SAFETY DATA SHEETS

Learn more about product specifications

SAFETY DATA SHEETS

Learn more about product specifications

HANDBOOK + PRODUCT INFO

FUGEO and our product research reports

HANDBOOK + PRODUCT INFO

FUGEO and our product research reports

LAWS & REGULATIONS

Laws and regulations we following

LAWS & REGULATIONS

Laws and regulations we following

PLASTIC CHEMICAL RESISTANCE

FUGEO materials’ chemical resistance data

PLASTIC CHEMICAL RESISTANCE

FUGEO materials’ chemical resistance data

FREQUENTLY ASKED QUESTIONS

Please feel free to contact us

FREQUENTLY ASKED QUESTIONS

Please feel free to contact us

FUGEO DEVELOPS DROP-IN MAGNESIUM SUBSTITUTE LONG FIBER COMPOSITES

FUGEO announced that it has expanded its LFT composite pellet product line to include drop-in replacements for die-cast magnesium.

FUGEO DEVELOPS DROP-IN MAGNESIUM SUBSTITUTE LONG FIBER COMPOSITES

FUGEO announced that it has expanded its LFT composite pellet product line to include drop-in replacements for die-cast magnesium.

ENHANCED SURFACE APPEARANCE DISTINGUISHES NFD'S VELOCITY SERIES OF LONG FIBER REINFORCED NYLON COMPO

FUGEO recently revealed the enhanced aesthetic capabilities of its high flow nylon long fiber reinforced composites.

ENHANCED SURFACE APPEARANCE DISTINGUISHES NFD'S VELOCITY SERIES OF LONG FIBER REINFORCED NYLON COMPO

FUGEO recently revealed the enhanced aesthetic capabilities of its high flow nylon long fiber reinforced composites.